Let’s talk about maintenance. Some view it as a hassle and something that is only done when absolutely necessary. Others see it as a necessity, a basic function required to keep an operation running smoothly. Every industry and every product is different. But one thing is for sure, in order to keep your shop running at peak performance, some type of maintenance will be required. When looking at options, there are three main maintenance theories followed, all of which have both positive and negative aspects.

Run to Failure (RTF)

The RTF maintenance theory is very easy to explain; you simply run your machine until it does not function properly or fails. Some may consider this to be a lazy or care free approach but there is actually logical reasoning for this method. With only 15% to 20% of equipment failures being age related and the other 80% to 85% being completed time random events, some feel this is the more economical approach to maintenance. By running equipment until failure you are sure to be servicing the issue and not replacing parts that are still viable. This can save you on replacement part cost, as well as labor. The downside to RTF however, can be massive. The main factor being the unknown, you don’t know when the machine will fail, and thus could be at a very busy point in your shop or business. This could end up costing you not only time and money but future customers. Another issue with the RTF plan is repair. Many times running equipment to failure can cause excessive peripheral damage; damage that may have been avoided with other maintenance plans.

Preventative

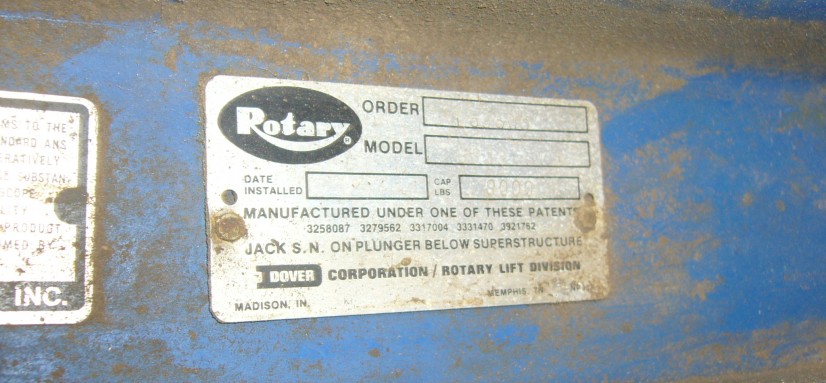

Preventative maintenance (PM) is another plan followed by businesses both large and small. It is driven by time, meter or event based triggers. The tasks that are undertaken during PM’s are pre-set, based on a variety of factors including age and the manufacturer’s recommendations. The theory is that certain parts will degrade over time and therefore are replaced prior to failure. The positive of using PM is a shop can plan for maintenance and can schedule it during a low volume time period. The negative with PM is that 80%-85% of failures are not time or age related. They are completely random. Since it is based solely on a time frame, it does not consider other factors like how often or how rigorously is it used. For example, a Rotary Lift installed in a home garage, cycled once or twice a week, would not incur the same wear as a Rotary placed in a high volume dealership. But, in the PM plan, the components would be changed out at the same time interval. With this you run the risk of replacing parts that are still viable, thus increasing your overall maintenance cost.

Predictive

Predictive or condition based maintenance is yet another way to maintain your shop’s equipment. The essential basis behind predictive methodology is to “predict” when an issue will occur by directly monitoring the equipment during normal operation. Periodically taking samples or monitoring certain aspects of known failure points would allow you to discover an issue before it occurs. By using predictive maintenance and identifying a potential problem, you can then schedule the repair when it will minimize impact of productivity. Here’s an example: instead of routinely changing the oil in your car every 3,000 miles, you may take an oil sample and only replace once the oil degrades beyond a certain point. This would ensure the car continues running smoothly, while only replacing degraded parts. Predictive maintenance does offer some advantages, but can be difficult to implement. You must create a monitoring schedule and adhere to it, which can be challenging. Routine checks also require time, costly equipment and even a third party.

Regardless of what maintenance plan you choose, for those with automotive lifts we recommend a yearly inspection. Whatever your business may be, there is a good chance you will need some sort of maintenance plan. Knowing your options and where to look for help is key to keeping your shop healthy and thriving.

Looking for certified inspectors? Call us today!